PPS system is a computer-aided production planning and control system. Their task is the operational control of production processes in industrial companies. We explain what advantages PPS systems have, in which industry they are needed and how to implement a PPS system.

The industry has faced numerous challenges over the years. Production processes are becoming more complex and competitive pressure is constantly increasing. In addition, there are new manufacturing processes that make planning and controlling the production processes noticeably more difficult.

Customer demand for individual products is also increasing. Nevertheless, production planning is still done manually in many companies. This a mistake, because in order to be competitive and successful in the long term, it pays to resort to intelligent software solutions at an early stage.

In this context, PPS systems support industrial companies in automating production planning both strategically and operationally. By analyzing internal production processes, managing the data, and delivering objective results, they help those responsible in the areas of production, purchasing, and sales to make better decisions and gain more planning control.

A PPS system is therefore necessary for most industries helpful – regardless of whether it is a medium-sized company or a large corporation. Above all, industrial companies with mechanical production that have complex products, numerous process participants, or several production sites benefit from a PPS system.

Typical sectors in which these factors are given are mechanical engineering and the electrical industry.

PPS systems overview: tasks and functions

PPS software makes it possible to quickly get an overview of what is happening in the company. You have the task of planning and controlling production processes in industrial companies in order to ensure optimal material stocks, compliance with production deadlines, and short throughput times.

Another function is the optimal use of resources to avoid constant rescheduling and unforeseen changes. Deviations from the agreed delivery time should be kept as small as possible. In addition, PPC systems serve the purpose of being able to react more quickly to market requirements in order to be able to flexibly fulfill accepted customer orders. This flexibility can be achieved by using a PPS system.

One of the central functions of a PPC system is to constantly check how the current production capacities are turning out. This is particularly advantageous when it comes to the question of whether new customer orders can currently be accepted. The production program is also constantly monitored. If there are delays in individual orders, the PPS system automatically responds in order to communicate the delay as early as possible.

Objectives and advantages of PPS systems

The aim of a PPC system is to simplify, optimize and automate the production planning and control of industrial companies in order to ensure better reaction and delivery times. PPS systems also reduce throughput times in production. Downtimes can also be kept as short as possible.

By continuously monitoring the production process, PPS systems help to identify and prevent impending faults at an early stage. This results in improved efficiency and increased adherence to schedules.

The calculation of personnel, machine, manufacturing, and material costs are also made easier, which means that those responsible in the areas of production, purchasing, and sales are able to calculate the production costs to keep them as low as possible.

It is essential that the software solution is optimally tailored to the company in order to be able to efficiently master various challenges in the production process.

PPS system overview: What does the market for PPS solutions look like?

The market for PPS systems is large. Standard solutions that users can configure themselves are a dime a dozen. This makes it possible to adapt the software solution precisely to your own company, even if you cannot afford a special software solution.

The development and structure usually take place in the form of modules. These are individual components that can be put together using the modular principle. It is not uncommon for individual modules to be geared specifically to the various sectors within the industry.

For larger companies with more differentiated requirements, standard solutions are often not sufficient. A classic example is an automotive industry, whose products have become increasingly complex in recent years. Individual software developments are usually used here.

This specialization has the advantage that it is much easier to respond to individual requirements. However, the programs are also more expensive to purchase. For this reason, small and medium-sized companies prefer standard solutions that are tailored to their respective customer groups.

When choosing a suitable software solution, what matters most is the company’s challenges and production processes. There is no one-size-fits-all solution. Our catalog of PPS systems can help to get an initial overview of the PPS market.

Difficulties and challenges in introducing a PPS system

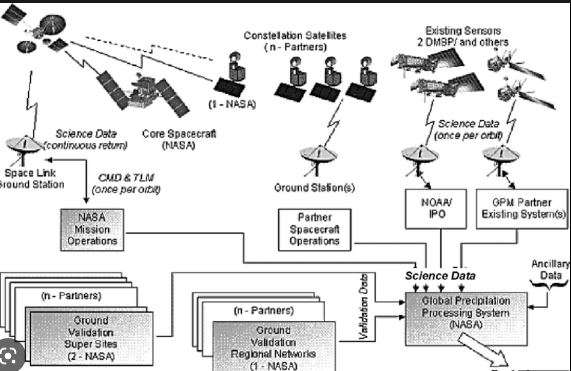

Modern production planning is far too complex to be controlled by a single software solution. For this reason, PPC systems are often embedded in comprehensive ERP systems that offer numerous additional functions so that tasks and processes can be carried out smoothly at the company level.

Seamless communication between the PPS solution and ERP system is essential here because the great potential of a PPS system can only be fully exploited when as much data as possible from the different company areas is recorded and available.

This applies to general master data as well as to existing order data. Accordingly, it is important to ensure a uniform database when introducing a PPS system.

In addition, careful planning and a structured approach are required, because the introduction of a PPS system does not take place overnight. First of all, the implementation is associated with a large financial, time, and personnel effort that should by no means be underestimated.

Another challenge when introducing a PPC system is to question processes that have been established for many years. This often meets with resistance from employees, who first have to get used to it. It is therefore important to explain the advantages of the new processes at an early stage.

Production planning and control in times of Industry 4.0

In times of Industry 4.0, no industrial company will be able to avoid using a PPS system in the long term. Outdated software solutions are increasingly reaching their limits here. It is important to implement a PPS system to support production processes intelligently and proactively – and thus to be successful and competitive in the long term.

In order be able to achieve the highest possible degree of automation, PPS systems should be able to communicate as seamlessly as possible with adjacent areas, including the ERP software in particular.